Top to bottom – tatting hook, Presto needle threader, button hook, sley tool, citrus peeler, latch hook, tambour hook, leather working tool made from nail, rug hook

Not every hooked tool is a crochet hook. So what are some of the common hooked tools mistaken for crochet hooks and how do you know? When confronted with a hooked tool that may or may not be a crochet hook, the first thing to do is to try and crochet with it. If you can’t crochet smoothly and rhythmically, it’s not a crochet hook. If it hurts your fingers or hand, it’s not a crochet hook. Pictured above are some hooks often mistaken for crochet hooks. Here’s a little about each.

Tatting Hooks

Tatting hooks are often distinguished by their short length. They are usually under 3″ and sometimes advertised as children’s crochet hooks which they are not. You can use the bone one above to crochet but without the long handle of a regular crochet hook to stabilize the hook against your hand, work does not flow very smoothly.

These pictures show both a tatting hook and a crochet hook from a Ladies Necessities set. Note that the hooks are set in the handles at different angles. It is difficult and uncomfortable to crochet with the tatting hook because of both the short length and angle of hook.

Presto Needle Threader

The Presto Needle Threader was designed to thread sewing machine needles. The spring loaded hook will collapse when inserting the hook into a stitch.

Button Hook

Button hooks have a large open hook. They were used for fastening shoe buttons. Slightly smaller hooks were made for fastening glove buttons. The hook catches when trying to pull the yarn through a stitch. You may find these with the same (and sometimes elaborate) handles as tatting and crochet hooks as they were included in Ladies Necessities.

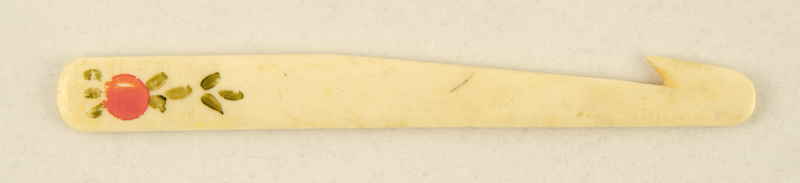

Sley Tools

I often wish these were crochet hooks as they were sometimes made of decoratively carved ivory like the two pictured above. Sley tools are used when warping a loom to pull threads through the reeds and have to be narrow. Sley tools are usually rectangular or oval in cross section with the narrowest width in line with the hook. When crocheting, you try to hold the hook on the narrow side of the rectangular hook or pointy ends of the oval.

Citrus Peeler

These wide flat tools are citrus peelers. Like a sley tool, the hook it at the wrong angle to crochet with easily. If it has an orange painted on it or says Souvenir of Florida, it’s a citrus peeler.

Latch Hook

This tiny latch hook was used to repair runs in (knitted) silk stockings. The hook is basically one hook from a knitting machine mounted in a handle. The latch usually doesn’t open when crocheting leaving the yarn trapped in the hook. Large latch hooks are used for rug making.

Tambour Hook

A tambour hook (bottom in photo above) usually has a screw that tightens against the needle (hook) to hold it in place. The screw serves a second purpose. The opening of the needle is aligned with the screw so you can maintain orientation of the needle as you pick up the thread underneath the work where you can not see (you catch the thread “blind”). Without an orientation guide, the needle would roll out of position as you work. If you try to crochet with a tambour hook, you find your fingers constantly bump into the screw. The earliest crochet hook patents were for handles that secured the needle by methods other than an exposed screw (top in photo above). Tambour hooks and crochet hooks with matching handles were sometimes found in Ladies Necessities.

Leather Working Tools

Heavy leather tack was sewn together by hand. An awl or punch made matching holes in two pieces of leather to be sewn together. A hooked tool pulled heavy thread or leather lacing through the holes forming a loop and a second piece of thread or lacing passed through the loop. The first thread or lacing was tightened until the crossing of the two centered in the holes – like the top and bobbin threads on a sewing machine. Leather workers might make their own tools like the shaped nail above.

Rug Hooks

Rug hooks come with and without latches. When you try to crochet with these, you want to hold the hook down on the round metal part instead of on the handle. This makes the hook hard to hold and lets the hook rotate out of position as you crochet. The chunky handles give a better grip when pulling yarn or fabric through the mesh base of the rug but get in the way when crocheting.